Manufacturing Solutions

Your Partner for Smart Manufacturing Solutions

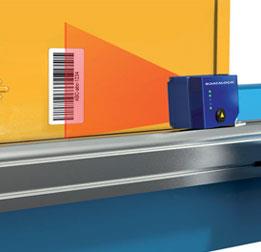

Manufacturing is easier and more reliable with Datalogic identification devices. Datalogic technology detects object presence, safeguards workers with light curtains, assures product quality with vision sensors, and identifies items using laser marking.

Process and product traceability are assured by fixed industrial and handheld barcode readers, scanners, and mobile computers that track items through the manufacturing process and on to distribution.

APPLICATIONS

Automotive manufacturing relies on a coordinated effort of manual and automated systems to deliver productivity, profitability, and traceability. Datalogic delivers vision detection and inspection systems that keep production moving. Datalogic industrial bar code readers, laser marking solutions and handheld data capture products maintain supply chain visibility from raw materials through subassembly inventory, work in process, and finished goods.

|

|

|

|

|

| Direct Part Marking | Quality Inspection | Tires Assembly Tracking | Tires Sorting & Shipping | Wip Traceability |

IMPORTANCE OF FOOD AND BEVERAGE TRACEABILITY

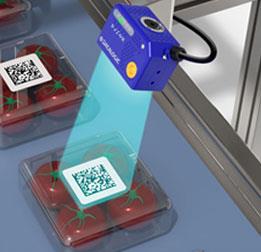

Food and beverage (F&B) traceability is indispensable in today’s fast-paced world. It ensures accurate tracking in production operations, efficient inventory management, and swift issue identification and remediation. Real-time data collection is essential for effective traceability in the production process.

Manufacturers can gain valuable insights by capturing detailed information, enabling them to make informed decisions and optimize their operations. Traceability also plays a pivotal role in ensuring F&B safety. In the event of a recall or contamination, the ability to trace product origin and movement becomes critical for safeguarding consumer health.

This guide explores technology’s multifaceted benefits and practical applications in F&B traceability. Whether you are a food manufacturer, distributor, or retailer, understanding the available technologies for traceability is crucial for operational excellence and consumer satisfaction.

CHALLENGES OF FOOD & BEVERAGE TRACEABILITY

Implementing F&B traceability presents cost challenges, especially with existing production lines. Customization, space optimization, and labor-intensive installations contribute to these costs. Innovative technology solutions can help mitigate expenses and improve efficiency. To meet this challenge, traceability systems must be long-lasting and handle product tracking across all production phases and intralogistics throughout the supply chain. Analyzing traceability data is another challenge for manufacturers handling high volumes of products and packaging materials. Automated data collection systems simplify analysis, saving time and providing valuable insights for informed decision-making and operational excellence, as well as fostering transparent and sustainable customer relationships.

F&B manufacturers must comply with government regulations, especially when selling products globally. The right technology solutions ensure compliance with local, national, and international laws, facilitating smooth global trade operations.

FORWARD AND BACKWARD TRACEABILITY

Traceability in modern manufacturing organizations encompasses both forward and backward directions. Forward traceability tracks the entire production process – from raw materials to finished products, while backward traceability allows manufacturers to backtrack and identify production processes step-by-step.

Both types of traceability ensure operational integrity. When defects are found in finished products, manufacturers use traceability to identify the root cause and rectify the issue. But traceability is not a set-and-forget type of activity. Leading manufacturers adopt a continuous improvement approach by regularly checking traceability within their production sites. Tracing raw materials and performing mock recalls are standard assessment tools.

Robust traceability systems enable F&B manufacturers to proactively address issues, enhance product quality, ensure safety compliance, and maintain consumer trust and brand reputation.

TECHNOLOGY AND INNOVATION DRIVE F&B TRACEABILITY

Introducing new technologies is revolutionizing F&B traceability and enhancing efficiency and accuracy in tracking food from farm to fork. IoT, smart labels, and blockchain-based trackand-trace systems contribute to improved compliance with food safety standards, instilling consumer confidence in the products they purchase and consume.

Barcodes remain the primary product identification technology, making high-performance and reliable barcode readers integral to accurate traceability in fixed, hand-held, and mobile applications.

SUSTAINABILITY IS A REQUIREMENT

Consumers’ increasing awareness of their purchases’ environmental impact has driven rising demand for sustainable F&B products. This demand has spurred innovation in the food traceability industry, enabling companies to monitor and manage their supply chains to ensure sustainability.

Innovative approaches to food traceability emerged to meet the demand for transparency and sustainability, including blockchain-based systems for tracking and verifying the origin of food.

Additionally, introducing artificial intelligence (AI) and machine learning (ML) systems has enhanced automated data collection and analytics to ensure food quality and safety.

KEY TRACEABILITY REQUIREMENTS IN F&B MANUFACTURING

F&B manufacturers must meet several essential requirements to ensure effective traceability throughout production. These requirements include:

- Tracking single items with unique identifiers. This provides precise traceability at every step, process, and operation an item or batch undergoes.

- Logging manufacturing and routing steps, including timestamps, line-operator IDs, and tools used at each routing step. By recording this information, potential issues can be easily identified and addressed when necessary.

- Tracking serial numbers, batches, and lots of raw materials. When properly collected, this data enables effective traceability and facilitates other inventory-management functions.

- Implementing physical identifiers, such as individual item labeling and efficient barcode reading. These identifiers are essential for production traceability, optimized intralogistics and warehouse management, shop-floor operations, and inventory control.

- Conducting consistent quality control and periodic inspections. Inspections should always be logged, creating a traceable digital paper trail that helps maintain product integrity and compliance with quality standards.

By adhering to these traceability requirements, F&B manufacturers can establish reliable traceability systems, minimize errors, reduce waste, optimize operations, and ensure the delivery of high-quality and safe products to consumers.

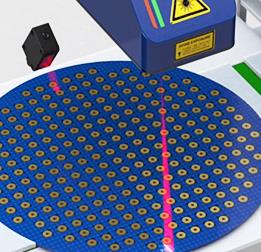

Like no other industry, electronics depends on vision systems for inspection and quality throughout the manufacturing process for PCB component placement, registration and marking identification, connector assembly inspection, and more. Datalogic keeps electronics manufacturers moving at peak performance with traceability solutions guaranteed by state of the art industrial bar code readers and laser marking solutions. When it comes to component inventory control, subassembly inventory, and supply chain visibility, Datalogic handheld scanners and mobile computers maximize efficiency for electronics production.

Automated machinery in used in all manufacturing sectors – Textile, Woodworking, Metalworking, Paper Mills, Printing, Ceramic Production, Glass Production and more. In each Datalogic solutions ensure materials and parts detection with sensors, operator protection with safety light curtains, product inspection with vision systems, and full traceability with bar code marking and readers.

Intralogistics completes the Manufacturing Process with applications like packaging end of line, palletizer, robotics, automated warehouses for pallets and crates, vertical storage carousels, Automated Guided Vehicles, and more. Datalogic solutions are found throughout intralogistics in safety devices for hazardous production areas, automatic object presence detection, dimensioning and position, complete traceability of item, box, bundle and pallet. Datalogic technology prepares goods for entering the distribution and retail supply chain.

|

|

|

|

|

| Palletizing | Manual Induction Warehouse Management | Warehouse Management | Cold Storage | Sorting and Shipping |

Steps after hitting the "submit" button:

- Our team will receive your contact information and reach out to you to schedule a chat.

- During the consultation, we will work with you to understand your unique business needs and recommend the right solutions to meet those needs.

- Once you have selected the solutions that are right for your business, we will work with you to place your order and get you up and running.

- Our expert support team will be there every step of the way to provide guidance and assistance as needed.

- With BlueStar, you can trust that you have a partner who is committed to your success and helping you take your business to the next level.